A breakthrough in second-generation biochemicals is the next major target on UPM’s R&D list, confirms Heikki Ilvespää, Vice President of Research & Development at UPM.

“We have made systematic progress in this sector, and we have already launched our first biochemical products such as GrowDex ja BioPiva on the market.”

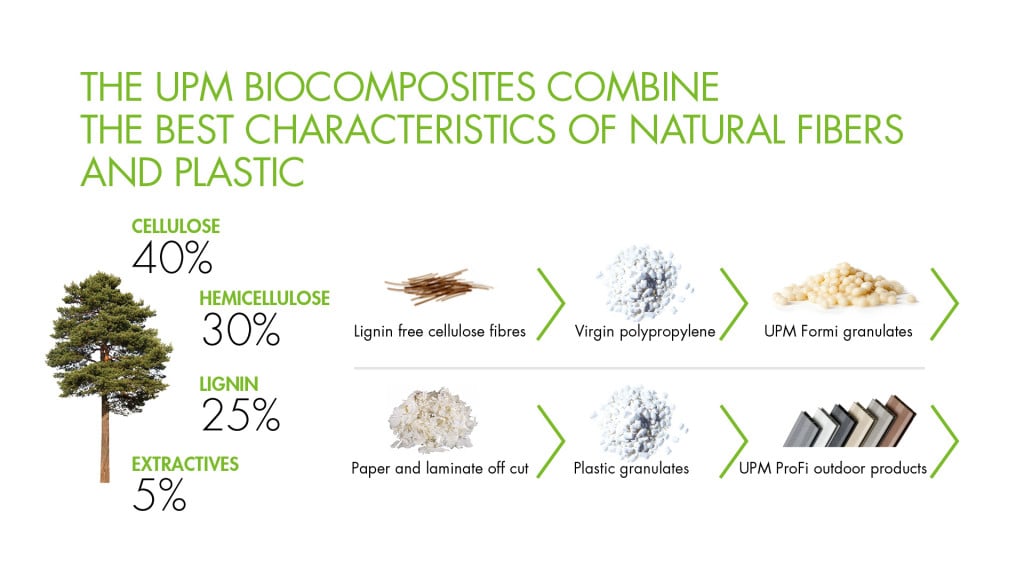

One potential application for biochemicals is manufacturing plastics from renewable raw materials.

“The pulp derived from wood can be broken down into sugars, which are processed further into chemical building blocks. In the future, materials produced in this way could be used to manufacture virtually any product that is currently made out of plastic, such as beverage bottles for the soft drink industry. The possibilities are virtually boundless,” he says.

Innovating for growth

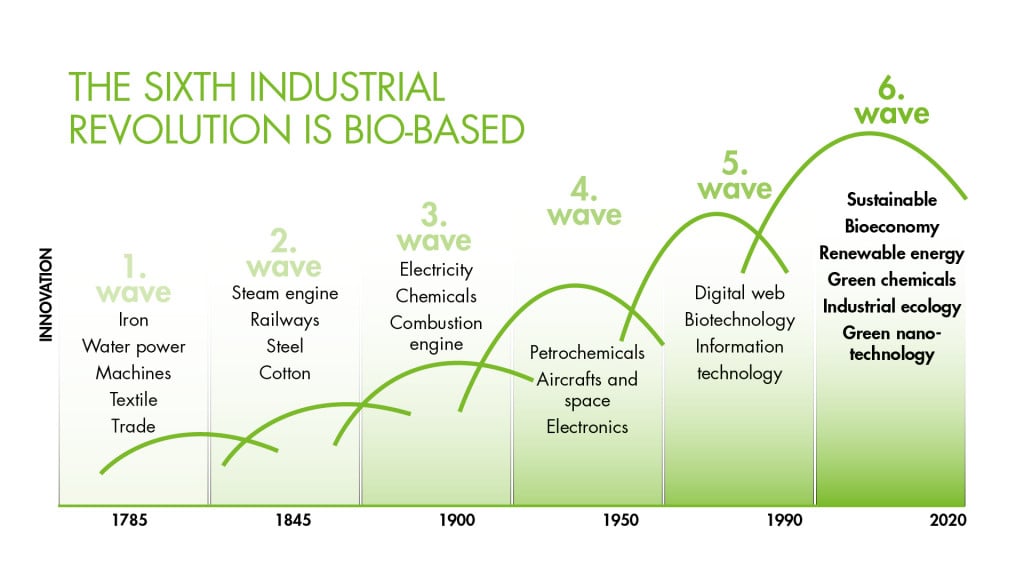

There is growing demand for products manufactured from biomaterials thanks to changing consumer preferences and efforts in various industries to reduce dependency on fossil-based products. The fight against climate change and greenhouse gas emissions is also fuelling the growth of the industry.

“Construction, packaging and hygiene products derived from wood and pulp and related product innovations represent a growing trend. This makes an excellent foundation for UPM’s short-term growth. The demand for products made from renewable materials just keeps on expanding,” Ilvespää explains.

Food industry titans are increasingly using bioplastics for packaging, and even car manufacturers are adopting more and more renewable and recyclable materials.

“UPM’s Biofore Concept Car proved that even cars can be made entirely from renewable and recyclable materials, all the way down to the fuel," Ilvespää notes.

Recipes for leftovers

Ilvespää believes that companies like UPM will play a significant role in the evolving economy based on renewable products and recycling.

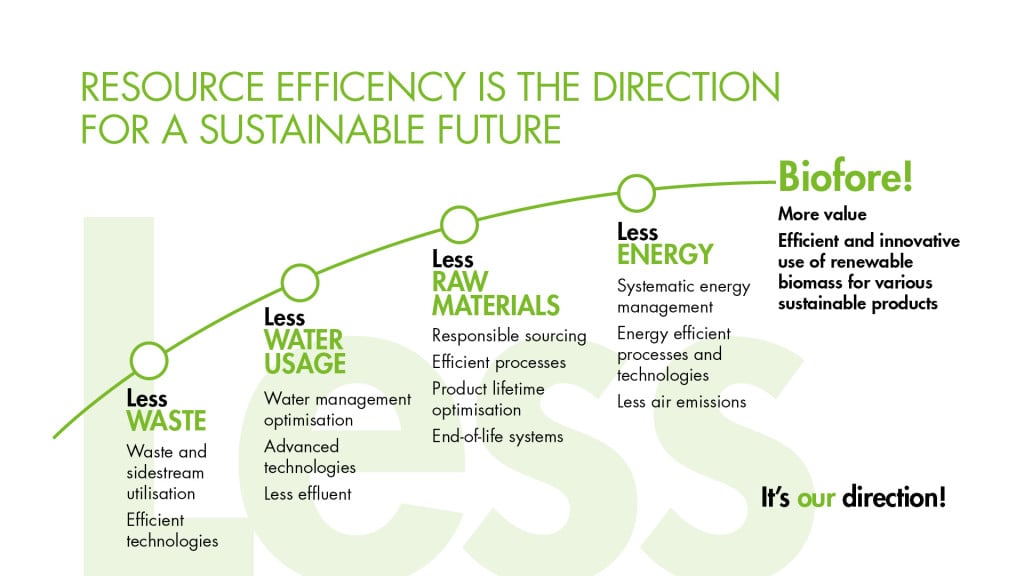

“Our essential strength lies in growing and sourcing renewable biomaterials in a sustainable manner, but our core competencies extend all the way to processing raw materials.”

“We strive to use as little raw material and energy as possible, and we even utilize by-products and leftover materials in our products. This model is ideal for the fast-growing bioeconomy and circular economy, which entails efficient utilization of scarce resources.”

Long goodbye to fossil economy

Ilvespää emphasizes that competitive pricing is absolutely crucial for renewable products such as biochemicals and biofuels, although environmental aspects are also becoming increasingly important as a selling point.

“Biochemical-based products have a smaller carbon footprint, so it’s important to start adopting sustainable solutions in the chemical industry as well. However, we need to carefully consider how much further the products should be processed in order to maximize the benefits.

“The closer we get to consumer goods, the higher the level of functionality required of the biomaterials. In addition to being environmentally friendly, the products should also perform better than fossil-based competitors to get the supply chain flowing smoothly,” Ilvespää adds.

Ilvespää admits that replacing the highly optimized fossil-based production chain with a new one based on renewable materials will be a vast and time-consuming task. A product’s journey from R&D to pilot phase and finally into production can easily take seven to ten years.

EU funding for biochemicals research work

Vesa Puoskari